Punch Laser Combination Machines - Product Range

From tapping, forming, marking, and even bending, the AMADA combination laser punch machines are hard to compete with. We are confident in delivering the most advanced technology when it comes to punch laser combination machines.

Designed to reduce manual operations, the AMADA combination laser punch machines are ideal for full-range processing. Our range features multiple punch laser combination machines to match a wide range of production needs.

- Punch & Laser Combination Machines

- System Upgrade

- Punching Tooling

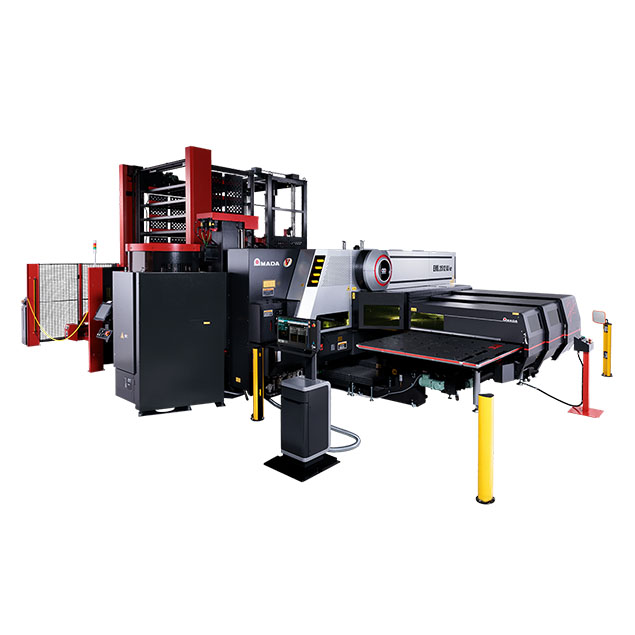

ACIES-AJe Series

The ACIES-AJe is the most advanced technology for punch/laser combination machines. Fiber laser combination machine, with Automatic Tool Changer offers high quality punching, forming and scratch free processing.

EML-AJe Series

Fiber laser combination machine, ideal for high mix of sheet metal components, reduced cost-per-part and improved profitability. Designed to minimise manual operations, it is ideal for full-range processing.

LC-C1AJe Series

Fiber laser combination machine, a versatile solution for any type of production. Bringing together the high performing electric punching system with the low energy consumption of AMADA’s fibre laser cutting.

Takeout loader (RMP-NTK)

Material supply and part stacking system capable of longer automatic operation. The RMP-NTK system automates single-pickup and loading of worksheets, and unloading and stacking of processed parts.

Cycle Loader With Storage Tower (ASR-N)

Material supply and part stacking system capable of longer automatic operation. This system automates single-pickup and loading of worksheet, and unloading and stacking of processed parts.

Takeout Loader With Storage Tower (AS-NTK)

Material supply and part stacking system capable of longer automatic operation. Parts are not microjointed, but separated from the skeleton, unloaded and stacked by the takeout loader.

Automated Material Storage & Retrieval System (MARS)

Operate 24 hours a day. Efficiently automates the storage, transportation, and control of worksheets and processed parts and enables longer operation of the plant by linking with blank cells.

NEX III Tooling

NEX III tooling can be disassembled, assembled and adjusted with a single button and without hand tools.

Contouring Tools

Precision nibbling on 0.5 mm centers allows for special processing without dedicated tooling.

Slotting Tools III

With AMADA’s Slotting Tools, joint mark-less processing is possible until the repositioning of the clamps.

ARFT (AMADA Rapid Forming Tools)

The time required for forming is significantly reduced.

V-Cut Tools

Cut a V-groove on the bend line (back side) of a worksheet. Making it possible to reduce the R at the bent part.

MPT Tapping Tools

Tapping (with both thread cutting and forming taps) can be performed on the turret punch press.

Chamfering Tools

Tool shapes are created to suit part shapes. Bottom burrs are coiled back to reduce the deburring time.

High Speed Marking Tools

Sorting of parts, formerly done manually. High-speed marking on workpieces helps to reduce secondary operations.

Standard Tooling

AMADA’s standard turret punch press tooling allows for high-quality processing.

Special Order Tooling

Special tools are also made to the specifications of customers.