Laser Metal Cutting Machine - Product Range

AMADA’s laser cutting machines are engineered to meet a wide range of manufacturing needs—maximising processing capacity while reducing production costs.

From the moment you inquire, we take the time to understand your production cycle and future growth plans. This allows us to recommend the most suitable solution for your factory, including the ideal cutting bed size and laser power capacity (kW).

You can choose between a standalone laser machine or a fully automated system, depending on your production goals.

When you invest in an AMADA laser cutting machine, you gain more than just a machine—you gain a complete support package including software, technical service, and spare parts, all designed to keep your operations running at peak efficiency.

- Laser Machines

- System Upgrade

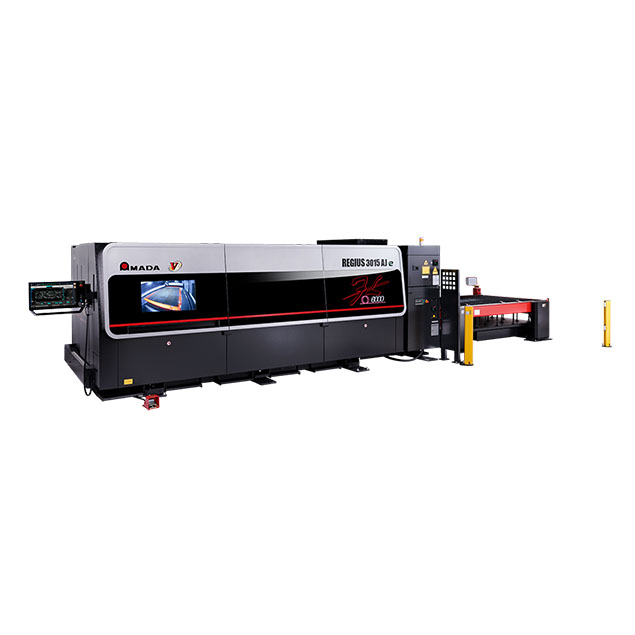

REGIUS-AJe Series

Next level laser processing. The REGIUS fibre laser cutting machine integrates 3-axis linear drive, AMADA’s original Variable Beam Control technology, the new Laser Integration System (LIS) functions and easy operation.

VENTIS-AJe Series *(LBC Technology)

High processing speed, and unrivalled cutting quality. The VENTIS-AJe is the biggest innovation in sheet metal cutting and introduces the next generation of fibre laser processing machines.

ENSIS-AJe Series

Ideal for a wide range of different materials and thicknesses. Available with 3, 6, 9 and 12kW engines developed by AMADA using 3 and 4kW diode modules, the ENSIS-AJe range considerably increases your production capacity.

ENSIS-3015RI

Flat, tube, channel and angle profile processing, all with a single machine. The fibre laser tube cutting machine ENSIS-RI can process round, square and rectangular tubes as well as channel and angle profiles.

BREVIS-1212AJ

An all-around Fiber Laser Machine. Introducing a compact fiber laser machine like never seen before. BREVIS is an all-around fiber laser machine that meets customer needs for cutting a wide range, from thin-to-thick materials.

Fork pallet changer (ASF/ASFH)

Shortest cycle time consistent with high-speed fiber laser cutting (ASFH). Long continuous operation with a stack of materials on the single-pickup unit.

Pallet changer (AS)

Long continuous operation is achieved with 10 shelves of processing pallets (a maximum of 15 pallets). Pop-up ball transfers facilitate the setting of worksheets and the sorting of parts.

Manipulator (MPL)

Long continuous operation. The fork unit automatically unloads and stacks processed worksheets. The second station makes it easy to process manually inserted worksheets.

Shuttle table (LST)

Continuous operation is enabled by offline setup with two processing pallets. Pop-up ball transfers facilitate the setting of worksheets and the sorting of parts. Microjoint-less processing is achieved.

Automated Material Storage & Retrieval System (MARS)

The MARS system allows for 24-hour operation. The number of rows and columns can be designed freely to meet specific shop spaces.

Large Format Laser Cutting Systems

- Large Format Laser Cutting Systems

- System Upgrade

ENSIS-6225AJ

Able to process larger sheets, or multiple sheets in a large cutting area. Available in 6 and 9kW variants, with all powers able to cut up to 25mm mild steel, stainless steel and aluminium.

LC VALSTER-6225AJ G

A rugged machine body designed for large plate processing. Available in 6 and 10kW variants, with both options featuring 6200mm x 2580mm maximum processing size.

Fork pallet changer (ASF/ASFH)

Shortest cycle time consistent with high-speed fiber laser cutting (ASFH). Long continuous operation with a stack of materials on the single-pickup unit.

Pallet changer (AS)

Long continuous operation is achieved with 10 shelves of processing pallets (a maximum of 15 pallets). Pop-up ball transfers facilitate the setting of worksheets and the sorting of parts.

Manipulator (MPL)

Long continuous operation. The fork unit automatically unloads and stacks processed worksheets. The second station makes it easy to process manually inserted worksheets.

Shuttle table (LST)

Continuous operation is enabled by offline setup with two processing pallets. Pop-up ball transfers facilitate the setting of worksheets and the sorting of parts. Microjoint-less processing is achieved.

Automated Material Storage & Retrieval System (MARS)

The MARS system allows for 24-hour operation. The number of rows and columns can be designed freely to meet specific shop spaces.

Metal Laser Cutting Machine - FAQs

An industrial laser cutting machine is equipped with a high-power density laser beam that enables quick and precise cutting. A high-quality metal cutting laser cutter for sale will process materials ranging from carbon steel, stainless steel, and aluminum alloy.

The principle behind a laser metal cutting machine is the heat generated by the laser beam that vaporises through metals. The sheet metal cutter laser beam moves through the material, cutting it into a pre-programmed shape. Importantly, a laser cutting machine features several key components like the nozzle, CNC controller, gas delivery system, and chiller. Appropriate auxiliary gas is used during cutting and oxygen is used to oxidise material in a steel cutting laser machine.

When looking for laser cutting machines for sale, you will have to make the choice between fiber and CO2 lasers. A fiber metal cutting laser cutter is known for narrower beam cutting, greater precision, and lower operating costs. This is largely due to electrical efficiency and solid-state construction. This industrial laser cutter is suitable for high-precission application on thinner sheet metal parts. On the other hand, a CO2 laser cutter for sale delivers wider beam width and usually more cutting power. It is suited for lower-precision cutting on thicker metals, such as a steel cutting laser cutting machine, for example. The initial cost of CO2 laser cutting machines for sale is typically lower but operating costs are higher per cut. Moreover, AMADA’s industrial laser cutter fiber technology has advanced beyond the capabilities of most CO2 lasers on the market.

Whether you are an experienced metalworking technician or a novice, AMADA offers cutting machine metal processing capabilities beyond expectation. Our fiber laser cutting machine range is driven by powerful technology with relatively low technical requirements.

The fiber laser cutting machine has been a game changer for the metal manufacturing industry worldwide. Its adoption has increased exponentially due to its high-speed, high-precision output which lowers operating costs and improves overall quality. While that’s the main factor why the fiber laser metal cutting machine is popular, here’s the key advantages in detail:

The beam quality and output on a fiber laser metal cutting machine are much more precise than its CO2 rivals. This translates into a metal and steel cutting laser machine that can carry out intricate details with maximum accuracy. It also results in higher cutting speeds while using the same or less power than metal cutting laser cutter alternatives.

A top industrial laser cutter for sale also has the ability to eliminate heat damage from workpieces. Cutting machine metal is done at such high precision levels that the beam won’t cause damage to the surrounding material. This is particularly necessary in industries that require a sheet metal cutter for very small components such as electronic devices.

In the medium to long term, an industrial laser cutting machine will reduce workshop overheads and operating costs. Of course, laser cutting machines for sale are not cheap. However, minimal maintenance requirements, easy operation, high output, and longevity of the sheet metal cutter, far outweigh the purchase price.

The software and technology behind the latest laser cutting machines for sale dramatically reduce inefficiencies throughout the production process. Design errors can be identified via a CNC sheet metal laser cutter and fixed pre-production, eliminating waste material in advance. Moreover, the technology behind the metal cutting laser cutter enables scalability with maximum efficiency and quality.