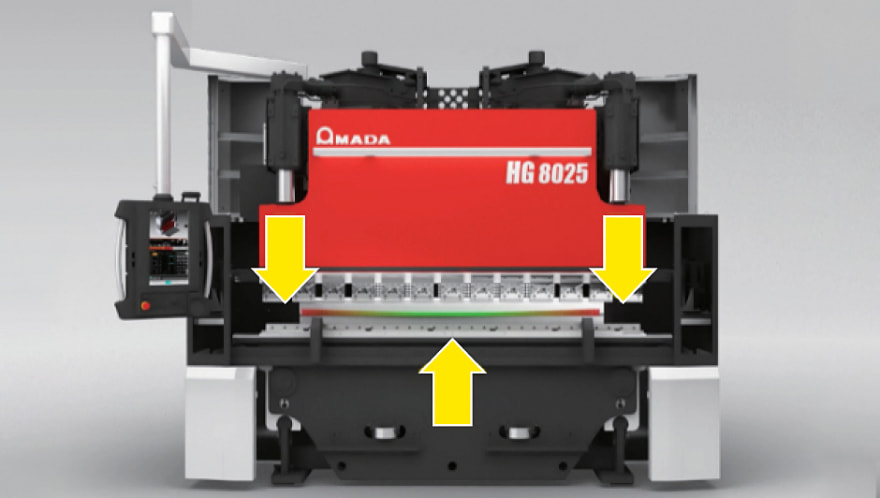

HG-ATC Series

Set-up times drastically reduced, the HG-ATC provides the ideal solution for processing variable-sized batches with complex tool layouts.

Modern businesses need solutions that are increasingly geared towards reducing production lead times and making processes more efficient.

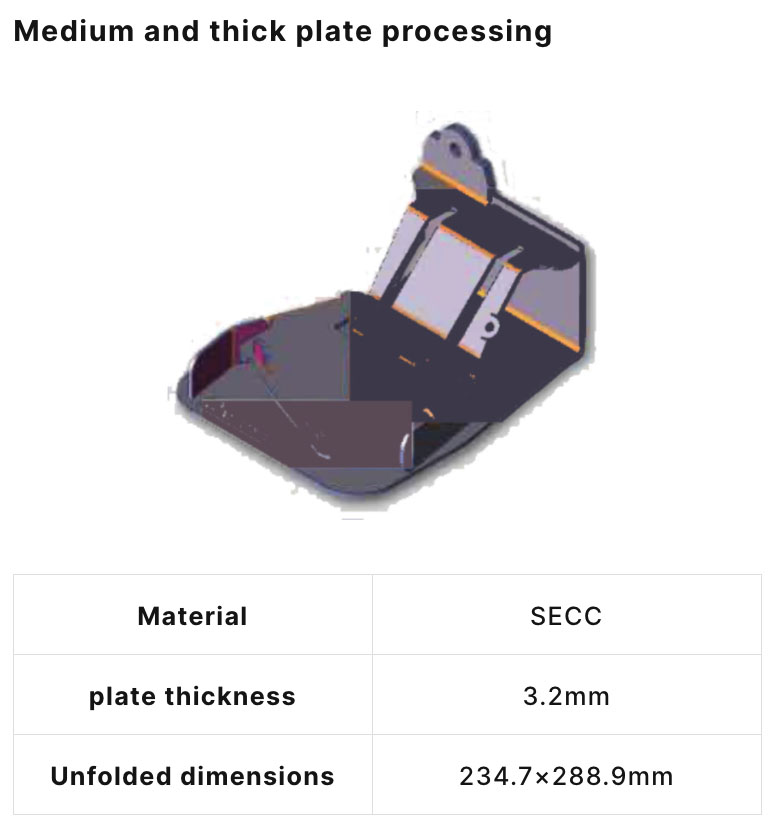

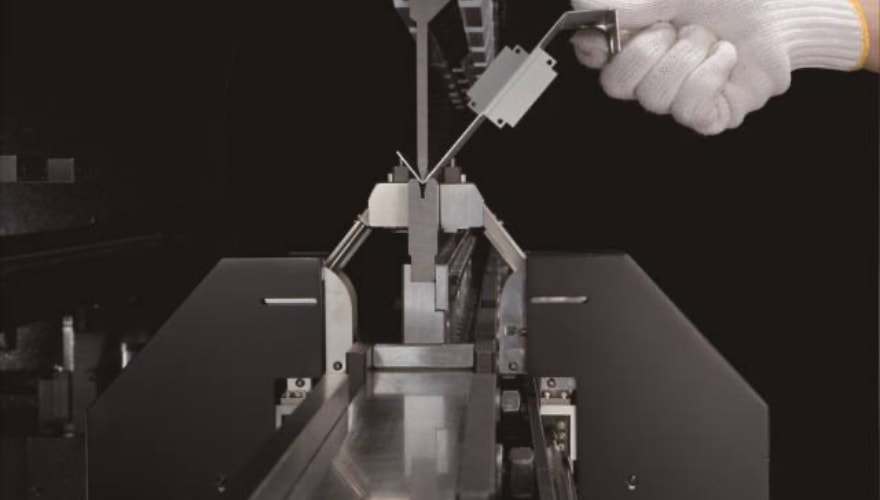

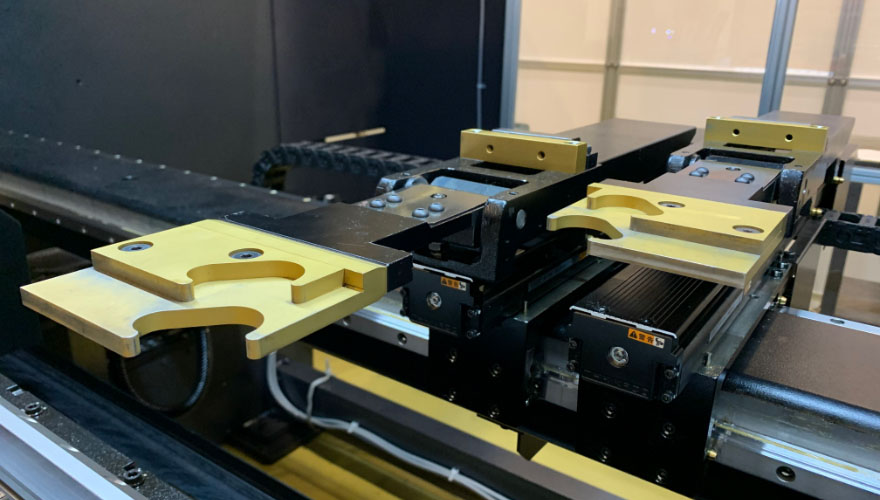

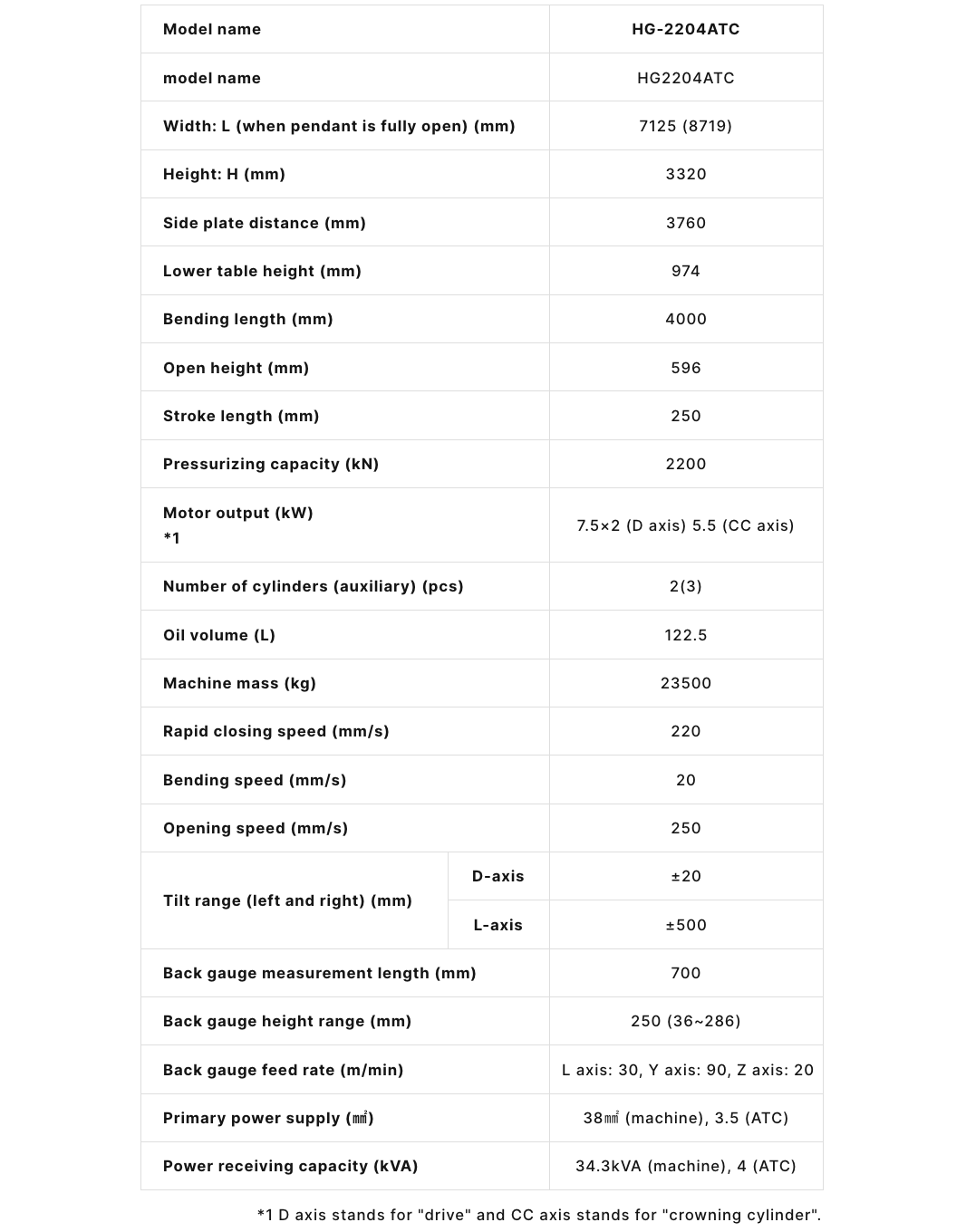

In bending, the critical aspects affecting productivity are tool setup and programming times. AMADA has designed the HG-ATC series available in the 2204 version, to provide the ideal solution for processing different sized batches with complex tool layouts. Thanks to the integrated ATC Automatic Tool Changer and powerful offline VPSS 3i Bend software, increasingly smaller lots and shorter lead times are no longer a problem. Set-up times are drastically reduced due to the Automatic Tool Changer, which can load tools in the most complex layouts, providing high efficiency and precision setup and the possibility for operators, with varying experience, to use the machine effectively.

This safety guide provides employers with important safety information they should know when they purchase AMADA products.

The safety guide describes the residual risks of machines. Implement risk reduction initiatives to suit the environment of your shop and the methods of using your machine, and conduct safety education for your employees as your responsibility as an employer. Several examples of safeguarding are introduced here. Safeguarding devices recommended by AMADA are offered as options. Please study and adopt them.

Download PDF: Press Brake Safety Guide